Your partner when it comes to belt grinding, belt sanding, polishing and deburring machines

IMM Maschinenbau is a leading manufacturer of belt grinding and polishing equipment for surface processing with more than 60 years experience. Our solutions range from polishing machines to turn-key manufacturing systems for the Power Generation, Aerospace and Medical industry. IMM Maschinenbau – the partner for your success!

History

IMM Maschinenbau GmbH is the successor of IBS GmbH and is one of the leading manufacturers of belt grinding and polishing equipment in the world. The sales and service activities in Germany are carried out directly, while there are IMM sales and service partners in more than 25 countries around the world. The design and manufacturing as well as the development of new innovative solutions for the advantage of our customers throughout the world all takes place at our Riederich location.

First METABO belt grinding machine for manual finishing

First automatic METABO belt grinding machine for grinding car bumpers

Automatic line for polishing car bumpers

Automatic machine for polishing bowls

Automatic machine for grinding welded seams

Automatic turbine blade grinding machine

First NC-controlled polishing machine

6-Axis NC-controlled turbine blade beld grinding machine

6-Axis custom made robot for grinding sanitary fittings

NC-controlled welded-seam grinding machine

Robotic-Centre for sanitary fittings using industry robots

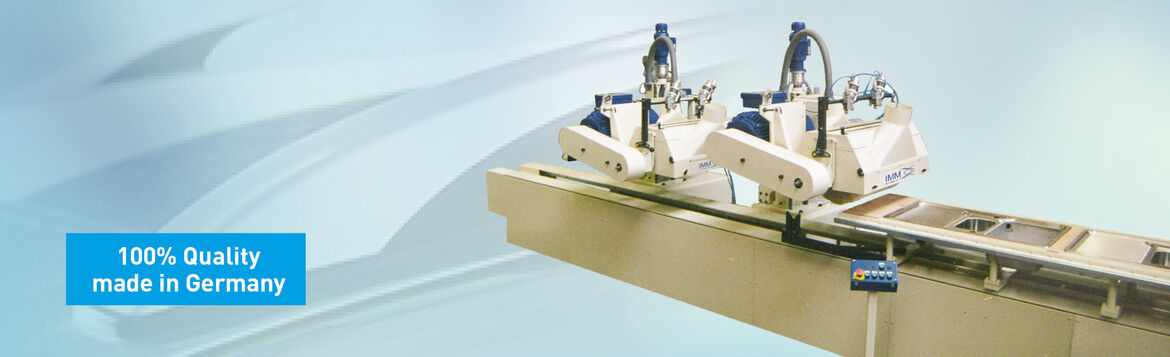

Robotic-Centre with leading heads

Robotic-Compact-Centre, concept series

Extrusion screw grinding machine, Type "sigma"

Indexing table machine with NC-Bowl-Polishing stations "alpha RT5"

Portal Polishing machine, Type "omega"

Robotic Centre for Bowl Processing, Type "concept alpha"

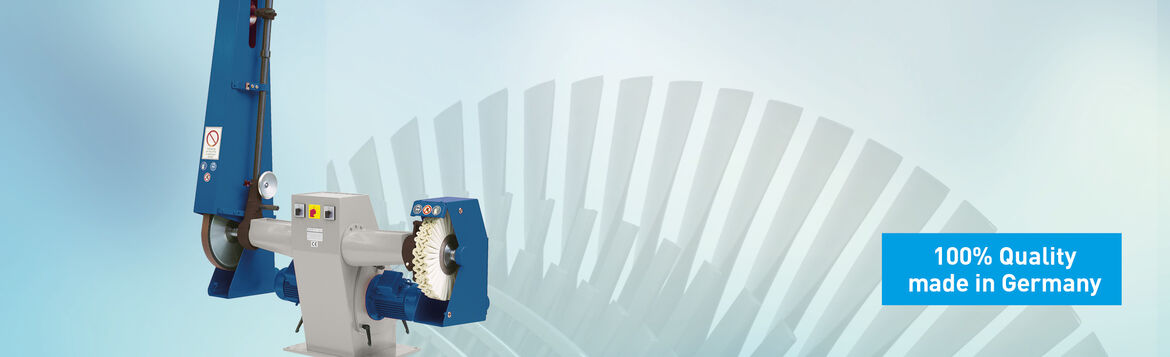

Manual grinding machine, Type 72712 for soft contact wheels and pneumatic tensioning arm

Manual grinding machine, Type 72713 for turbine blades with two contact wheel diameters

Turbine blade grinding machine for oversize blades, Type MTS

2006 Automatic Aircraft Lip Skin finishing machine RTS for the BOEING 787 Dreamliner

2007 Multi-Axis processing machine, type SPE for grinding, de-burring, brushing, milling and polishing

2008 Automatic 7 NC axis deburring machine, type SPE-MEP7 for aircraft engine rotatives, such as HPT, IPT and FAN disks

2008 The worlds first automatic, fully adaptive fan blade grinding/polishing system MTS-Adaptive for aero engine fan blades

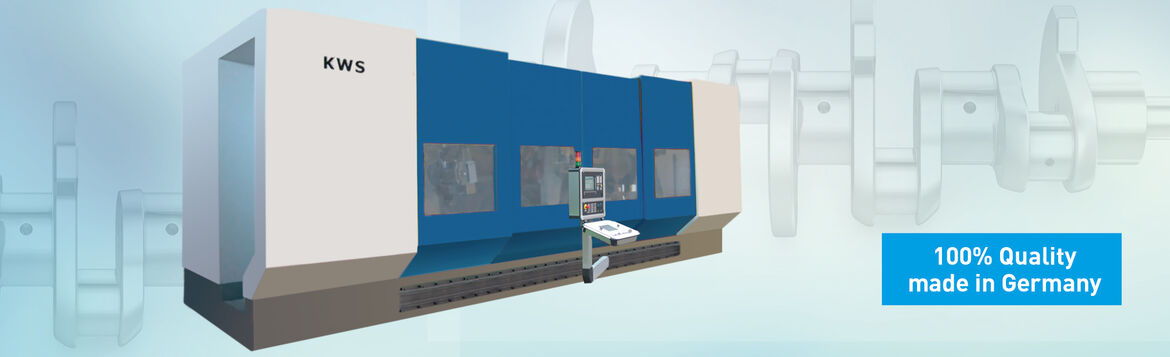

2010 Fully automatic NC belt grinding machine, type KWS-4500 for gas engine generator crank shafts up to 4500 mm

2011 Enhanced SPE NextGen for turbine blade polishing with innovative new axis configuration introduced at Hannovers EMO 2011

2013 Robotic Centre for tight bowl radius polishing, type VECTOR P1

2015 MTS NextGen with innovative integrated measuring for belt grinding of steam and gas turbine blades

2015 Move to our new site in Riederich, doubling our previous manufacturing floor space to over 14,000 ft²

Revised MTS with newly designed machine bed and servo motor driven belt head spindle.

The SPE grows up: Increased axes strokes now allow polishing and belt grinding of large turbine, compressor and stator blades of H and F Class turbines.

A demonstration and test facility is completed for our customers with a variety of belt grinding and polishing machines, polishing jacks, linishing machines and a wide range of abrasive belts, contact and polishing wheels.

Special adjustable belt head covers for safe belt grinding and polishing of surgical instruments and medical implants.

GAMMA CNC belt grinding machine with special attachment for belt grinding of welded seams and edge profiling using a special design slack belt unit.

![IMM [LIVE] IMM [LIVE]](/typo3conf/ext/bit_template/Resources/Public/Images/imm-logo.png)